Client Success Story

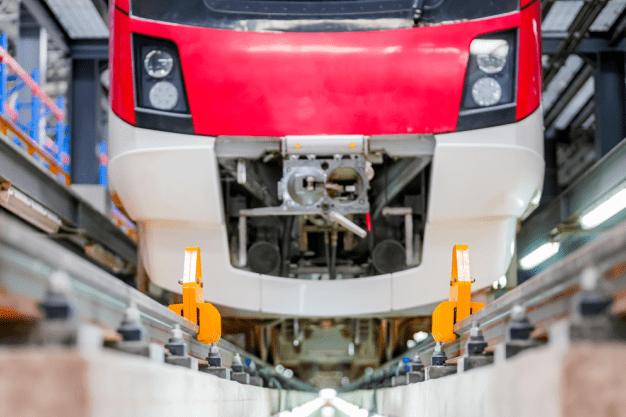

Rail - Electrical Harness Modelling for Subsystem Integration

Company

Rail

A rail vehicle manufacturer needed to integrate complex electrical subsystems while adhering to stringent European rail standards. Our team offered comprehensive Electrical Harness Modelling, wire routing, bundling, and connection design, ensuring compliance and reliability in challenging rail environments. Successful subsystem integration, meeting safety standards and streamlining production with detailed documentation.

Client Challenge

The rail vehicle manufacturer faced several challenges in integrating complex electrical subsystems while adhering to stringent European rail standards. Our team tackled these challenges by providing comprehensive Electrical Harness Modelling, wire routing, bundling, and connection design services. We ensured compliance and reliability in challenging rail environments by meticulously addressing safety standards and regulatory requirements. Through successful subsystem integration, we streamlined production processes and provided detailed documentation, facilitating efficient manufacturing and maintenance procedures.

Ideal Solution Proposed

Our expert electrical engineers conducted a comprehensive assessment of the client’s requirements. Utilizing our expertise in Electrical Harness Modelling and European rail standards, we proposed a solution that began with detailed wire bundle size and load calculations. We selected appropriate protection, connectors, and conduit to ensure robust electrical systems. Our team integrated manufacturing requirements into the design, performed dimensional stack-ups, and collaborated with various interfaces, such as interior, electrical, vehicle control, and vehicle head. The client successfully achieved seamless subsystem integration across their rail vehicles, meeting stringent safety and regulatory requirements. Our solution ensured the reliability and durability of electrical systems, even in challenging rail environments. We provided comprehensive documentation, including accurate bills of materials (BOM), assembly instructions, and manufacturing specifications, streamlining their production process. This case exemplifies our capability to provide specialized solutions for rail industry challenges, focusing on electrical harness modelling, compliance with European rail standards, and robust subsystem integration.